New Ventilation Range Expands Market Reach and Delivers Uncompromising Performance

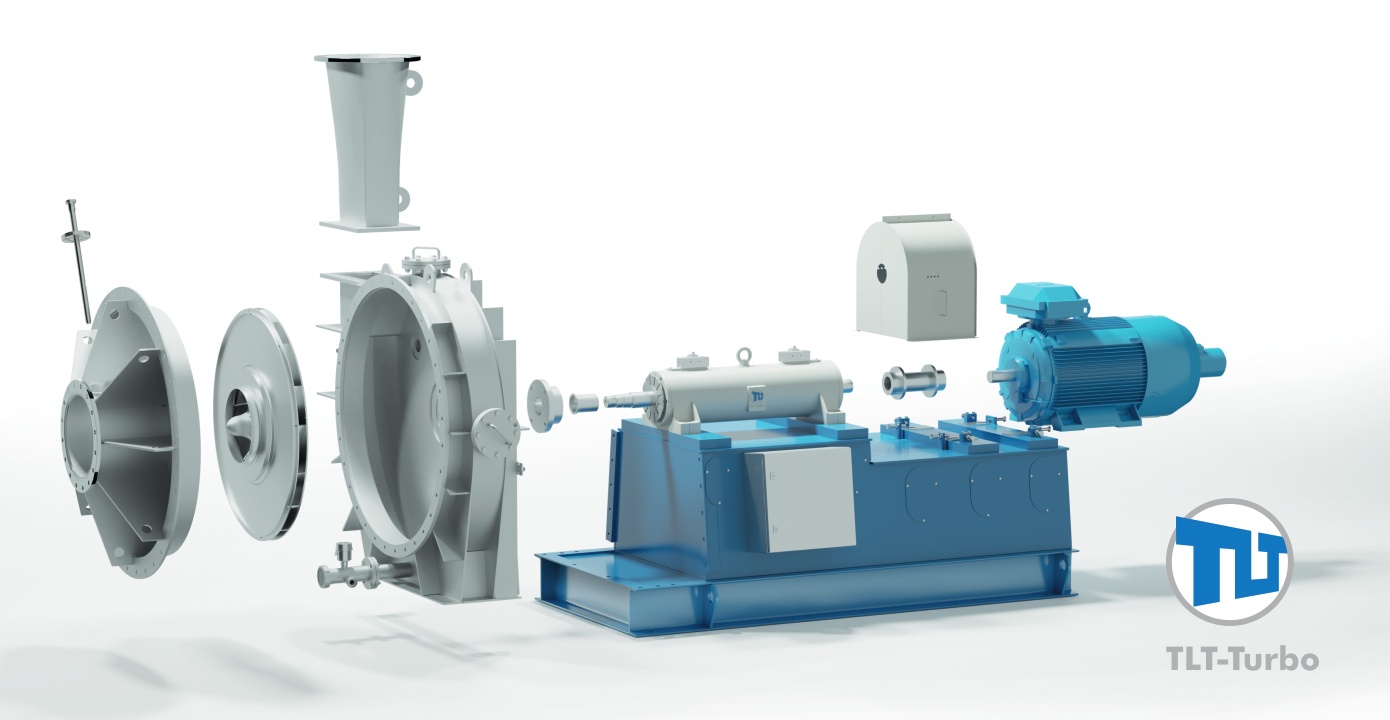

Global ventilation fans and systems manufacturer, TLT-Turbo GmbH, has announced the launch of their new Low Flow MVR Fan Series. As a more compact alternative to TLT-Turbo’s existing larger-capacity MVR range, the new low flow series promises the same uncompromising efficiency that clients have come to expect from TLT-Turbo ventilation equipment.

Having been in development for the past 18 months, this new addition to the MVR (Mechanical Vapor Recompression) range is characterized by having a significantly smaller and more compact size while still delivering higher efficiencies.

In comparison to the existing MVR range, these fans are designed for lower mass flows at medium inlet temperatures. “The maximum speed is 6500 rpm. This limitation is mainly due to the fact that there are no faster rotating motors available in this range and for this application,” explains Mario Schmidt, Head of Business Segment Vapor Fans, TLT-Turbo. He adds that this range is ideally suited to industrial applications focused on the concentration of liquids.

The new Low Flow MVR series elegantly combines all the advantages and features of all other TLT-Turbo MVR series, including maintenance-free, long wear hybrid ceramic bearings and high efficiencies as well as speed-, temperature- and vibration monitoring. The fans are designed to achieve temperature increases up to 11°C while maintaining efficiencies of up to 83%.

“The development of this range is an exceptional achievement of our R&D department and product management team. The expansion of our current MVR offering has allowed us to enter the small mass flows market which makes us more competitive.”

The design of the new series was carefully considered, ensuring that all major customer and application requirements are met. Schmidt explains that these fans are made to deliver on performance. “The fans are available 24/7 with a wide range of operating points and high efficiencies of up to 83% depending on inlet temperatures and specified temperature increases. In addition to this, the fans are VFD controlled.”

The highest quality and safety standards are met by using only high quality and proven components. The fans’ monitoring devices are included with the installation, and all models are rigorously tested, and FEM calculated. Like their larger counterparts, the Low Flow MVR Series is manufactured using hybrid ceramic bearings that are lifetime greased and can be operated for up to 10 years without requiring maintenance. To enhance this benefit for clients, TLT-Turbo introduced an additional device to the fan’s design that allows for the bearing to be re-greased from the outside in order to further simplify maintenance and to increase the fans’ service life. “Maintenance is made even easier for our customers with the option for them to make use of our remote performance and maintenance checks.”

The new Low Flow MVR Series is manufactured at TLT-Turbo’s dedicated facility based in Germany and is available globally. An order has already been secured for the supply of TLT-Turbo Low Flow MVR fans from a globally renowned manufacturer for installation at an instant coffee production facility in Colombia. “The securing of this contract has already caught the attention of other global coffee producers and bodes well for the continued growth of our MVR division,” says Schmidt.

“TLT-Turbo is known for redefining ventilation, and this means we constantly strive to set new standards. With respect to all previous MVR series, TLT-Turbo is the first manufacturer to use hybrid ceramic bearings. In addition, all TLT-Turbo MVR fans are aerodynamically optimized and offer high efficiency. For further developments, new materials and manufacturing methods are also continually investigated to ensure that our customers benefit from the latest innovations. Our MVR range has been trusted for use in applications with stringent hygienic requirements such as highly polished impellers and housings. This, and all the other innovations showcased in the new series is the result of an almost 150-year track record in the design and production of industrial fans,” Schmidt concludes.