The Next Generation of Mechanical Vapor Recompression Fans

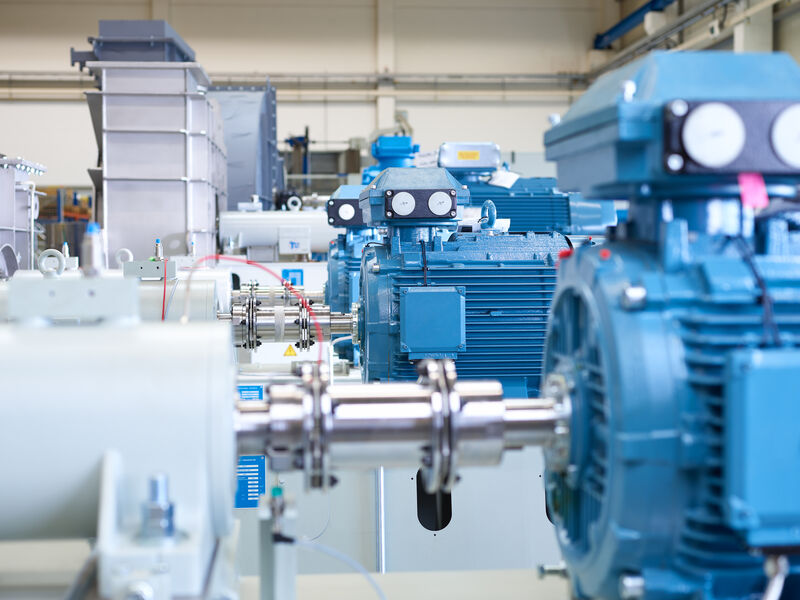

Evaporation and distillation processes are used in a wide variety of manufacturing and industrial processes. The most effective means of lowering the energy cost associated with the generation of heating steam is to use mechanical vapor recompression (MVR) fans. TLT-Turbo has developed a range of MVR fans – more innovative and technologically advanced than those currently on the market.

Innovative Use of Ceramic Hybrid Bearings

The use of hybrid bearings with steel rings combined with ceramic rollers has been established in many industrial applications and in the case of the TLT-Turbo MVR fan, hybrid ceramic bearings mean significantly lower maintenance requirements and better operational performance. The hybrid ceramic bearings used in TLT-Turbo MVR fans are life time greased and can be operated for up to 10 years without requiring maintenance. The installation of an oil supply unit is not required which eliminates the risk of contamination by oil leakage in processes with high hygienic standards. TLT-Turbo’s MVR fan also has an additional device that allows the bearings to be re-greased from the outside in order to further simplify maintenance and to increase the fans’ service life.

Features of TLT-Turbo’s Fan for Mechanical Vapor Recompression

- Wide range of fans available to suit specific performance requirements

- Utilization of energy efficient motors and converters

- Ceramic Hybrid Bearings result in long service life and low maintenance costs

- Flexible, custom designs available for specific requirements

Products Range

Broad Applications to Solve Diverse Industry Challenges

The TLT-Turbo MVR fan is suited to numerous applications in the chemical, pharmaceutical, waste water treatment, and the organic natural product production industries as well as in the food and beverage process and manufacturing sectors. To meet market demands, the TLT-Turbo MVR fan can achieve high temperature increases. It is also possible to connect several fans in series to achieve even higher temperature increases.

Client Support Services

We provide support at every point of your ventilation system lifecycle. We offer planning and design support at the start of your project to ensure that the final system meets your precise requirements and meets every safety standard. This is followed by manufacturing, transport, assembly supervision and commissioning services. We take aerodynamic acceptance measures to ensure that the system is functioning optimally. TLT-Turbo also offers reconstruction and optimization of existing systems.

Contact your nearest TLT-Turbo office to consult on the mechanical vapor recompression solution that fits your specific requirements.

Find out more