Modular Design Redefines Mine Ventilation Efficiency and Availability

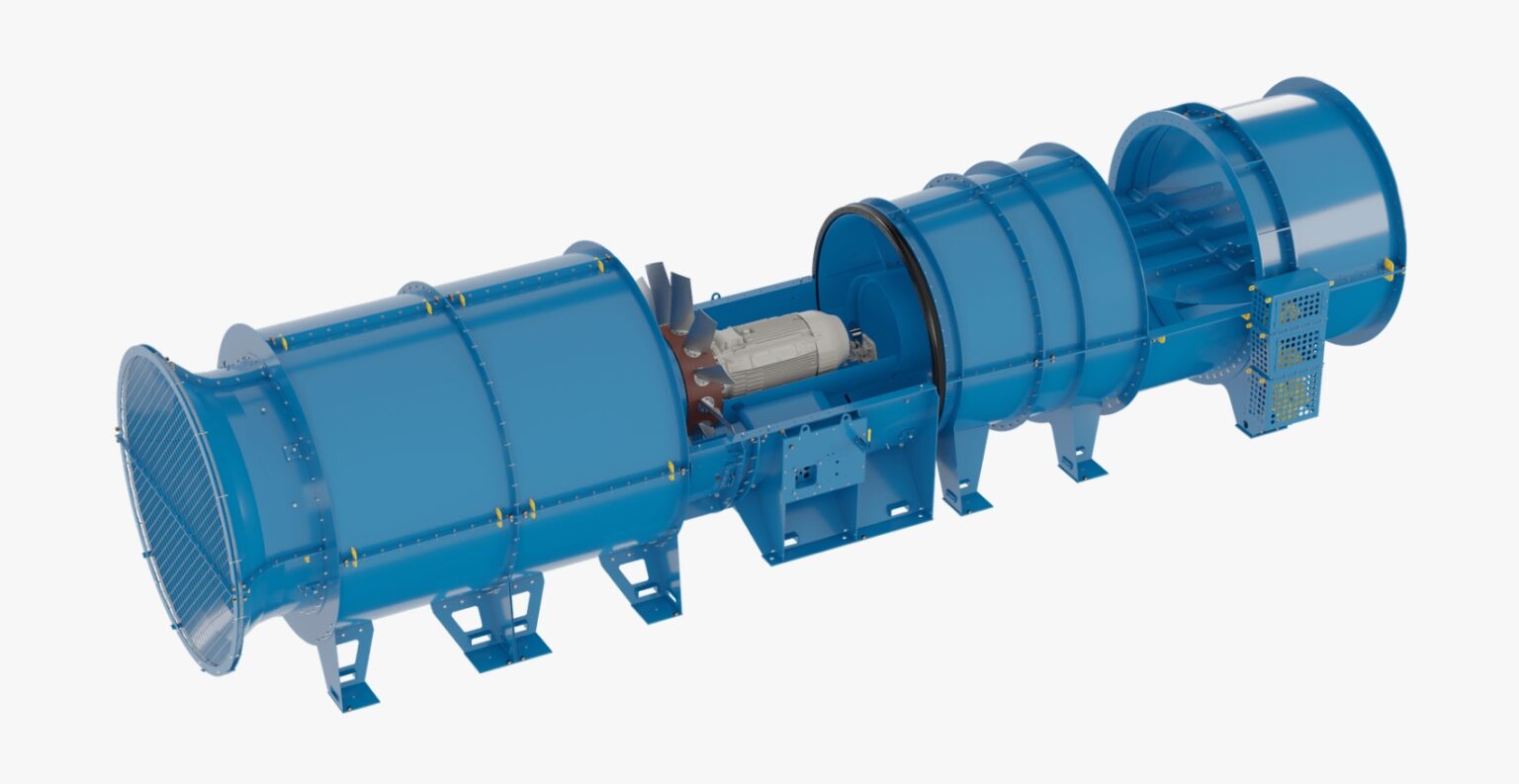

TLT-Turbo have released a modular mining ventilation fan concept that simplifies the planning of ventilation systems for customers while still providing the benefits that are synonymous with TLT-Turbo products including increased efficiency and lower power consumption. The Modular Mining Fan concept offers a range of modular solutions that cater to almost every ventilation requirement and aims to set a new standard for mine ventilation innovation.

The range offers a modular design that results in a well-engineered and efficient ventilation system at lower operational and maintenance costs. Customers have the flexibility to order required units and build on the system as their requirements grow – resulting in lower initial expenditure with more economical options for system expansion.

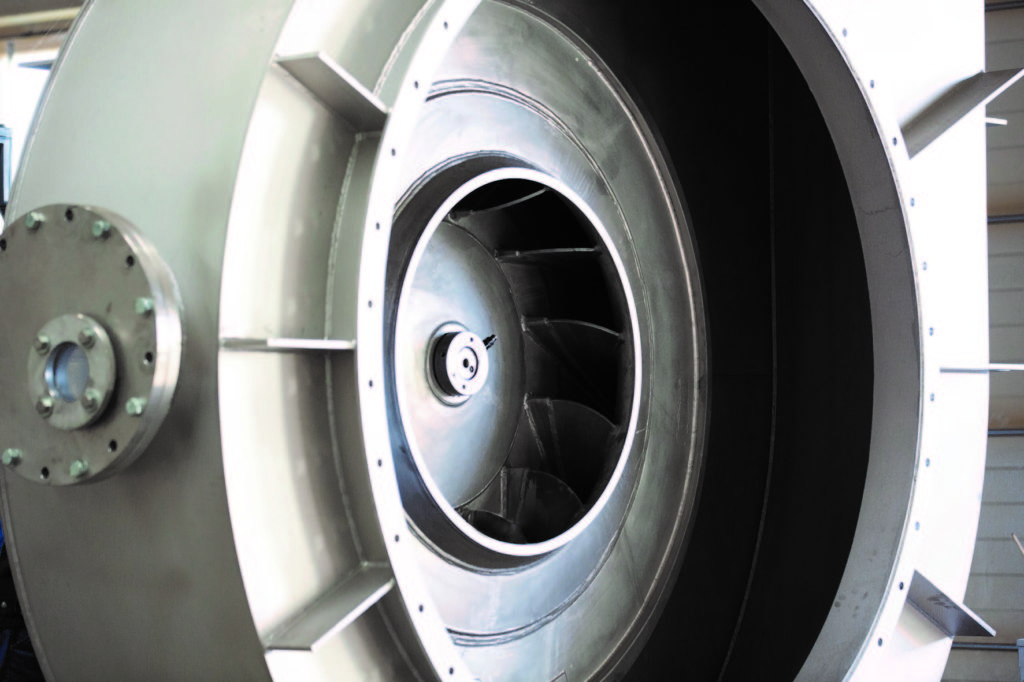

German engineering and extensive R&D have resulted in the highest product quality. This, paired with TLT-Turbo’s field-proven technology, provides a high-end pre-existing solution which means that mines will not incur the design and engineering costs that are usually associated with bespoke ventilation installations.

The modular concept makes it extremely convenient for customers in the mining industry to plan, design and optimize their ventilation systems to optimally benefit their operations. The modular approach eliminates guess work and ensures that the entire system can be planned to deliver predictable and accurate performance.

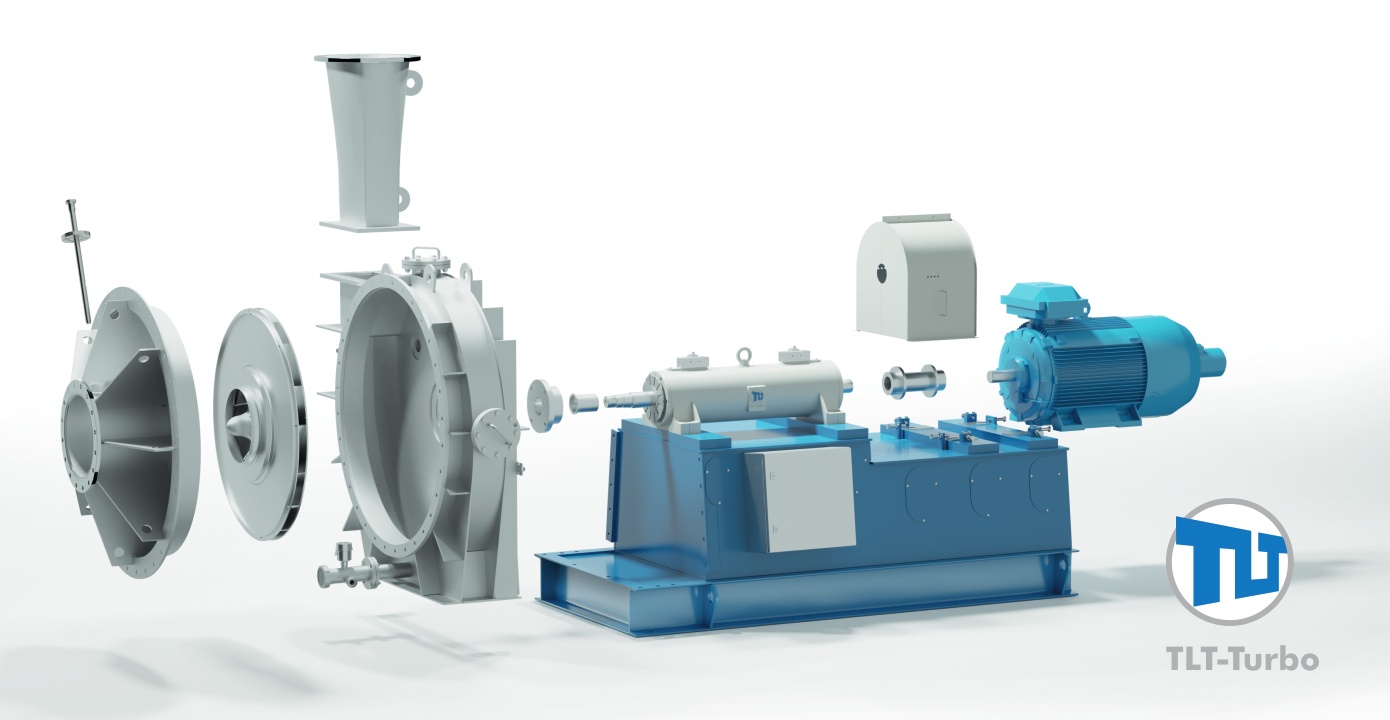

The modular design offers seven base fan sizes combined with six different hub sizes to ensure the right fit for all requirements. Numerous customizable and adaptable parts offer flexibility for specific customer needs. Add-ons have been developed for all seven base sizes allowing for modular pre-existing upgrades to meet individual requirements.

The modular components are designed to slot together, and no additional engineering is needed to ensure that different modules fit together to suit a specific operating environment. The advanced design ensures total fan efficiency of up to 90%, lowering the operating costs while maintaining full performance. This entire offering is available at lower initial costs with short lead times for supply.

All the modular components can be manufactured simultaneously and are commissioned and installed once completed. Expansion of an existing TLT-Turbo Modular Mining Fan system is a simple process as new components are slotted into the existing system with minimal effort. Typically, ventilation systems need to grow or be upgraded as production demands increase. Where a major overhaul would usually be required, TLT-Turbo’s modular installation can be expanded by installing additional components to the existing system to scale up ventilation capacity or replace existing modules with higher specifications to optimise or upgrade the system.

With the modules being manufactured at state-of-the-art TLT-Turbo manufacturing facilities, customers can be assured of the highest quality end product. Continual monitoring, testing and quality checks are conducted at every stage of the manufacturing process. Well considered opportunities for varied combinations ensure shorter manufacturing and delivery lead times at lower costs to get your project running faster and smoother.

Contact TLT-Turbo to find out how the Modular Mining Fan range can benefit your operation, or visit https://www.tlt-turbo.com/en/product-and-services/mining-fans/modular-mining-fans/ to find out more.